1947

Panzeri Carlo srl opens for business: a factory manufacturing light parts and finished lighting products

Quality, tradition and innovation. These are the bedrock values of Panzeri, a company that has a 70-year history of producing lighting and selling the Made in Italy brand gracing the most exclusive interiors and exteriors worldwide.

Read moreLighting crafted with care and attention to detail, designed to light and enhance both indoor and outdoor spaces, with a myriad of solutions in terms of style. Panzeri lights are the ideal choice for Architects, Interior Designers and creatives planning to incorporate quality lighting into their private and public design schemes. The superior quality of each product is undoubtedly the driving factor in this choice. Hand-picked raw materials, expert tradition and manual skill for the most exclusive detailing, innovative and cutting-edge techniques in the field of LED technology, and all-Italian design: all of these factors have been key to the success of this company that, from day one – led by its founder Carlo Panzeri – has been steadfast in the belief that it would set a benchmark in the lighting industry.

Panzeri is now something of a fixture at the industry's main shows – Euroluce in Milan, Saloni Worldwide in Moscow, and Frankfurt's Light+Building – and its lights are distributed in over 40 countries across the world, enjoying particular success in Italy, Germany, Austria, Russia and North America.

The company is also actively involved in local organizations. Panzeri is a member of the Monza and Brianza branch of Confindustria, the confederation of Italian industry; of the FederlegnoArredo Assoluce domestic lighting association; of the ADI industrial design association; and has been recognized as a landmark business by the Monza and Brianza branch of the Italian Chamber of Commerce.

Providing the best solution for your every specific need since 1947. Panzeri's story has always been inextricably linked to the core values that epitomize the company's philosophy: quality, research and innovation. Mapping out the company's path in those early days was founder Carlo Panzeri, an entrepreneur with extensive experience in the technical and engineering sector who, in 1947, created a company specialized in producing chandelier parts.

Read moreMapping out the company's path in those early days was founder Carlo Panzeri, an entrepreneur with extensive experience in the technical and engineering sector who, in 1947, created a company specialized in producing chandelier parts. A modern manufacturing facility with cutting-edge equipment and machinery, geared to offer its customers the best solution catering to their specific requirements. Carlo Panzeri has been successful in handing down his values to the next generation, who have inherited their father's winning business culture, and remain true to his legacy. Over the years, the company has grown and evolved, eventually opting to take the plunge in the '90s and launch its own line of lighting products with considerable success, managing to merge an impressive legacy of tradition and craftsmanship with hi-tech content of the highest calibre. Drawing on a unique wealth of tradition and craftsmanship, the latest advanced technologies, premium materials, and creative Italian design flair, Panzeri light fixtures are now regarded as high-end decor items and lighting solutions, the ideal choice for the most ambitious projects.

Panzeri Carlo srl opens for business: a factory manufacturing light parts and finished lighting products

New industrial facility is built and, over the coming years, will be extended considerably

First patent filed for pulley device

First halogen floor lamp launched (T201 model)

First big-selling product (T80 model)

PANZERI brand launched

Debut showing at Euroluce and Milan's Salone del Mobile furniture show

Company exhibits at international events in Cologne, Frankfurt, Valencia, Moscow and London

Trasferimento nel nuovo e moderno stabilimento industriale a Biassono

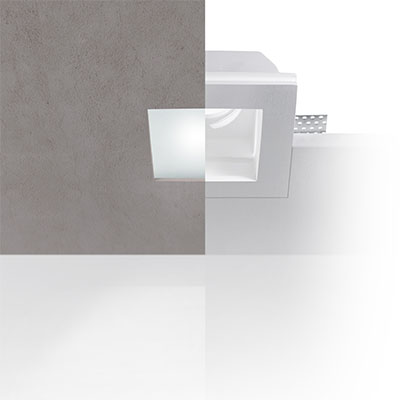

PureWhite architectural collection moved to the new, modern industrial facility in Biassono Lancio

R&D department created, focusing on LED technology

Laser cutting machinery introduced and new projects and collaborations developed

1 brand, 2 collections (Design & Architectural), true to the Made in Italy brand

One of the added values of greatest importance to a company like Panzeri is the wealth of tradition and craftsmanship handed down over the course of its 70-year journey. A journey experienced first-hand and related by entrepreneurs who love what they do and who, together with a group of highly qualified, passionate managers, have had the strength and courage to keep reinventing themselves.

Read more

The key to the success that the company has achieved thus far essentially lies in adopting a future-oriented approach, while keeping a watchful eye on the past. A past that makes this company increasingly proud of the goals achieved and vindicates its ambition to be the go-to supplier for demanding Architects, Interior Designers and Creatives seeking a solution to their individual lighting needs.

The production process starts with hunting down the best raw materials. Steel, iron, aluminium and brass are hand-picked from various suppliers in the market to guarantee raw materials of unrivalled quality. Cutting, cleaning and polishing are all carried out in-house using cutting-edge machinery and technologies. Some of the more unique decorations are carried out with sophisticated handcrafting techniques, such as the application of gold leaf, a procedure that calls for extensive experience and precise manual skill.

Once manufactured, products have to pass thorough quality testing and, only where they are judged to meet the strictest standards are they placed in packaging specially strengthened to ensure its precious cargo is fully protected during transit and delivery. Panzeri also has 400 m2 of warehousing featuring a fully automated vertical storage system able to house over 1,100 pallets, equating to a traditional 4,000m2 warehouse.

The modern automation system means the warehouse handles interactions with the order system without the need for operator intervention.

Another of the traits making Panzeri one of the key players in the interior design and lighting solutions market is the ability to tailor its offerings to the clientele's individual requirements.

Read moreAn increasingly discerning and demanding clientele in search of some of the most elaborate and original details and features who see their every creative demand answered in Panzeri's custom-made offerings.

The company's offering is the product of its expert tradition and experience teamed with modern technologies and a production cycle handled by the company from start to finish. In addition, the sourcing of glass through partnerships with Italian suppliers not only allows the company to offer a bespoke product in terms of design and materials, but also gives access to a raw material that, where possible, boasts exclusive and customizable features. Whether dealing with a design collection or its architectural counterpart, whether the product is custom made from scratch or adapted from an existing product, Panzeri's goal is to create a specific solution catering to each individual lighting requirement.

For any company in a position to offer the market a good, competitive product, quality is without a doubt top of the list when it comes to standards that need to be met. And Panzeri is no exception.

Read more